Install an evaporative cooler to provide efficient cooling in a dry climate:

See the Compliance Tab for related codes and standards requirements, and criteria to meet national programs such as DOE’s Zero Energy Ready Home program, ENERGY STAR Single-Family New Homes, and Indoor airPLUS.

Description DescriptionEvaporative coolers can be an effective and less expensive alternative to standard air conditioners for cooling your home if you live in a dry climate. Evaporative coolers (known in the past as swamp coolers) use evaporation and blowing air to provide cooling. They can use about one-fourth as much energy as central air conditioners and cost less than half the price to install and operate. Evaporative cooling can be used as a backup to traditional air conditioning or as the primary cooling for the home. See the guide “Passive and Low-Energy Cooling” for information on incorporating evaporative cooling into an overall low-energy cooling strategy. Evaporative coolers work best in dry climates where the outdoor relative humidity during the cooling season is low.

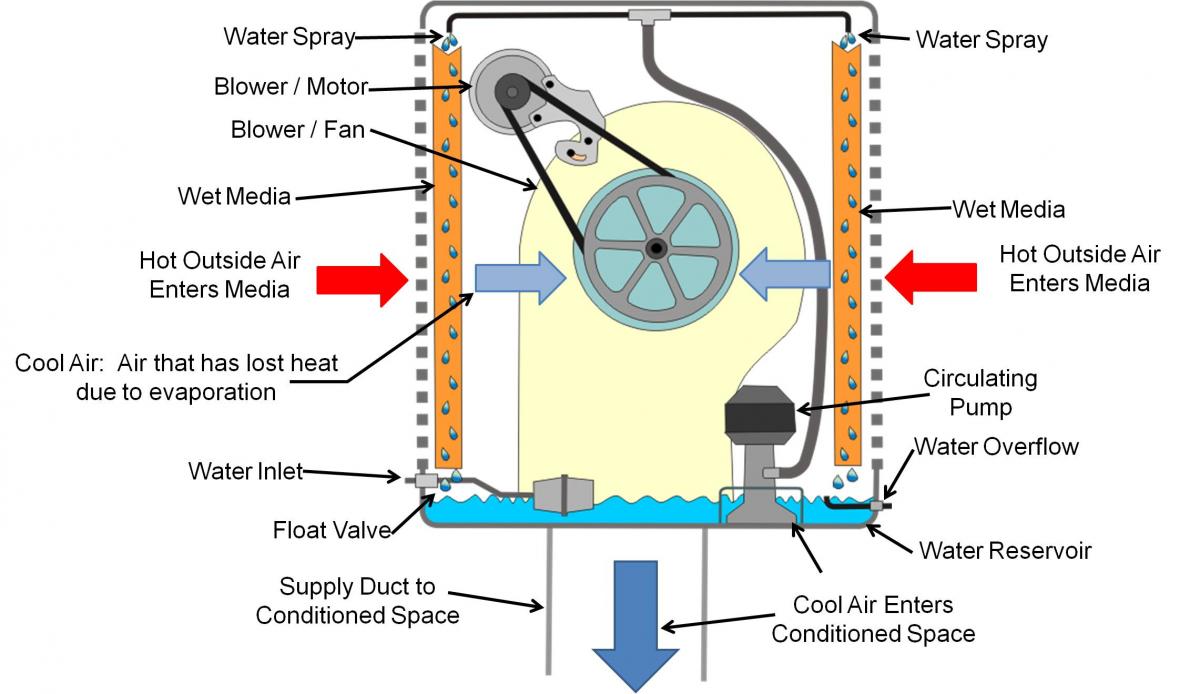

How Direct Evaporative Coolers Work

Direct evaporative coolers are the simplest and most common type of residential evaporative equipment. A direct evaporative cooler is a fairly simple device consisting of a box-like housing that contains a large blower fan and 8- to 12-inch-thick sponge-like filter media made of treated cellulose, fiberglass, plastic foam, or shredded aspen fibers, that is constantly soaked with water from a sprayer and recirculating pump located in the unit. The blower fan pulls in outside air and blows it through the sponge-like media and into the building. The flowing air evaporates some of the water, which can reduce the temperature of the air entering the home by 15°F to 40°F. The evaporatively cooled air is blown directly into the home; hence the term direct evaporative cooler. Unlike standard air conditioning, direct evaporative coolers increase rather than decrease the humidity in the air. Figure 1 shows the basic concept of evaporative cooling.

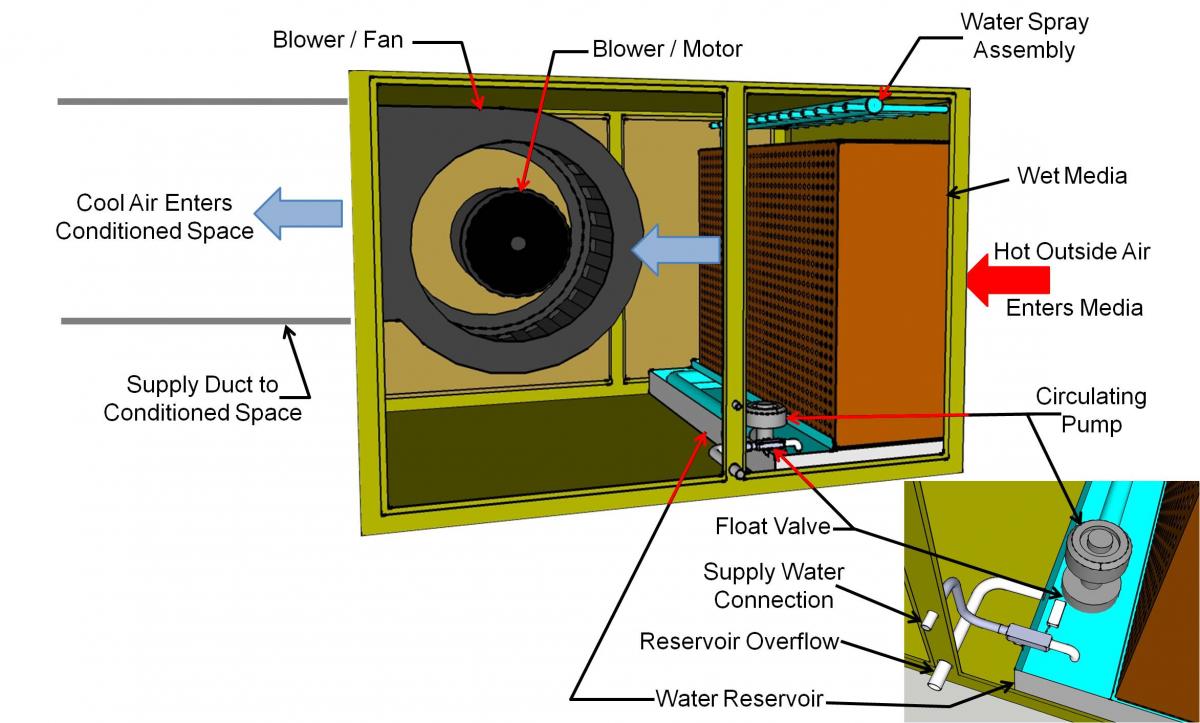

Traditional direct evaporative coolers (“swamp coolers”) were often mounted on the roof. These units had multiple inlets and panels of evaporative media. Air would be pulled in through the sides of the unit, pass through the media, then blow downwards into the home (Figure 2). These down-flow systems are typically connected to a duct system located in the attic. Roof-mounted systems can be difficult to access for maintenance and can lead to leaks in the roof. Ground-mounted or wall-mounted systems are generally easier to access and maintain than roof-mounted systems, and they will not cause roof leaks (Figure 3).

Newer direct evaporative cooler designs use a single inlet with a thicker evaporative media (Figure 4). This arrangement leads to better evaporative performance and more flexibility for ground and wall-mounted arrangements. A modern evaporative cooler should have at least two fan speeds and a vent-only option. The vent-only operation allows the unit to be used as a house fan during mild weather. In vent-only mode, the unit can act similarly to a whole-house fan, providing cool, dry outdoor air for direct cooling. See the guide “Whole-House Fans" for more information.

Operation and Maintenance

Evaporative coolers require regular maintenance to keep the water reservoir clean and odor-free. Maintenance should be done at least twice a year, when the unit is first started up in the spring and when it is shut down in the winter. In the spring, the filter media should be replaced or cleaned, the belt inspected for proper tension, and the cabinet cleaned and inspected for damage. In the winter, the water line should be shut off, the pan should be drained and cleaned, and a winter cover should be installed to prevent dirt and dust from getting inside the unit. During the cooling season, the drain pan should be emptied whenever the cooler will be idle for more than a few days as standing water left in the pan can become a breeding ground for mosquitos and bacteria, including Legionella (the cause of Legionnaires’ Disease).

If the local water has a high mineral content, a bleed-off valve can be installed in the recirculating line to drain off water and reduce mineral concentrations; however, this can increase water usage by 10% to 50%. A more efficient alternative is to install an auto-flush system (also called a dump pump) that empties the cooler pan and brings in clean water at regular intervals (e.g., every 8 to 12 hours of operation) to reduce mineral buildup.

Although evaporative coolers are typically less expensive to purchase, install, and operate than refrigerant-based cooling systems; their water usage and water costs must be taken into account. Annual water use varies based on the number of hours run and the dryness of the air. For example, for a 1,500 ft 2 home, annual water use for an evaporative cooler without a bleed-off valve could range from 2,980 gallons in Santa Fe, to 7,261 gallons in Albuquerque, to 12,457 gallons in Las Cruces, New Mexico. Increase these numbers 50% if the cooler has a bleed-off valve (SWEEP 2007).

The incoming air from an evaporative cooler is not recirculated inside the house but is blown through the house and must have a way to exit. When operating, evaporative coolers bring in enough fresh air to completely replace house air every 2 to 3 minutes. For the system to work correctly, doors or windows must be opened to provide a path for the air to exit. Alternatively, ceiling exhaust vents can be installed. These typically exhaust directly into the attic, which must be a vented attic. The exhaust vents usually come with a barometric damper that automatically opens when the cooler is on. They may also have a mechanically controlled damper which requires electricity and control wiring to operate. Either type of damper should operate such that it is closed during the heating season and in the summer if the home is using standard air conditioning when not operating the evaporative cooler. For every 1,000 CFM of air delivery, 2 ft 2 of unrestricted air relief is required (PG&E 2004). Because the air will tend to flow to open outlets, some zoning of cooling can be achieved by opening windows or vents in those rooms where cooling is desired.

The evaporative cooler can be installed to blow air directly into a central location in the home or it can be connected to ductwork to distribute the air to different rooms. Central-location installations work well for compact homes with open floor plans. Ducted systems are needed for larger houses with hallways and multiple bedrooms. Design an efficient air distribution system with a compact duct layout in accord with ACCA Manual D. Install ducts properly for maximum airflow and efficiency.

The cooling effectiveness of an evaporative cooler is dependent on the temperature difference between the dry-bulb and wet-bulb temperature of the entering air, the velocity of the air moving through the media, and the quality and condition of the evaporative media.

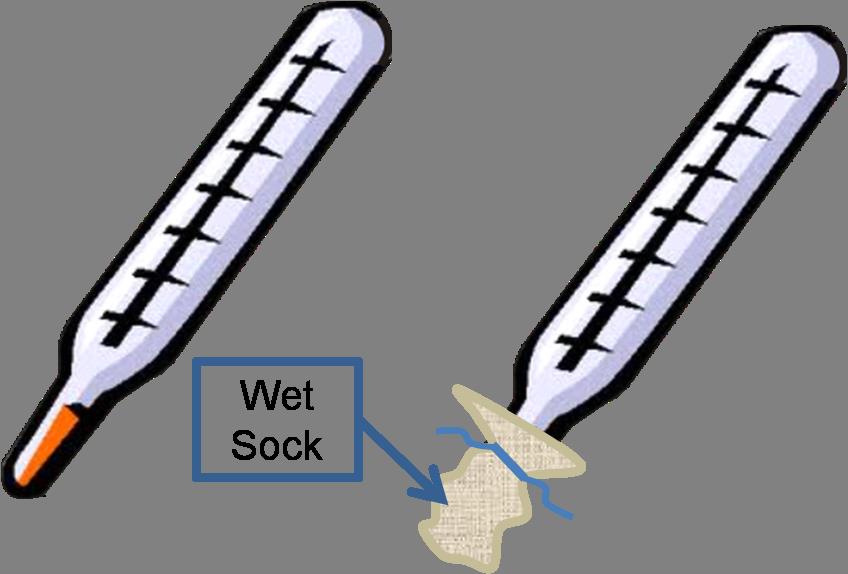

When we think of outdoor temperature, we are usually thinking of dry-bulb temperature, which is the temperature of the air measured using a common, ordinary thermometer. Wet-bulb temperature is measured with a thermometer that has a wet sock or cloth wick wrapped around the bulb (Figure 5). As the water in the sock evaporates, the sock loses heat and cools the thermometer bulb, bringing the thermometer reading down to the wet-bulb temperature. The wet-bulb temperature is the lowest temperature that can be reached through evaporation.

The wet-bulb temperature depends on how humid the air is. The more humid the air, the higher the wet-bulb temperature. Hence, the temperature difference between the dry-bulb temperature and wet-bulb temperature is dependent on the amount of water vapor in the ambient air, as measured by relative humidity. Wet-bulb temperature is directly related to relative humidity (if the dry-bulb temperature and relative humidity are known, the wet-bulb temperature can be determined using a psychrometric chart or online calculator). When the relative humidity is 100%, the wet-bulb temperature will be equal to the dry-bulb temperature (so evaporative cooling cannot occur). If the relative humidity is lower than 100%, the wet-bulb temperature will be lower than the dry-bulb temperature. The difference between the wet-bulb temperature and the dry-bulb temperature is known as the wet-bulb depression. The greater the wet-bulb depression, the better an evaporative cooler works.

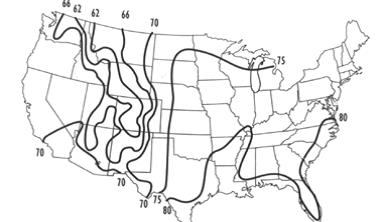

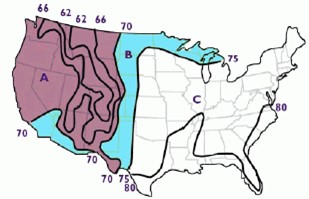

For this reason, evaporative coolers work well in dry areas of the country such as the Southwest. An area can be evaluated based on its 1% design conditions. The 1% design temperature is nearly the highest temperature a region will typically see: it is statistically exceeded only 1% of the time. For example, Phoenix, Arizona, has a 1% cooling design outdoor dry-bulb temperature of 108°F and a coincidental wet-bulb temperature of 70°F (ACCA Manual J, Table 1, 1% conditions). The wet-bulb depression would be 38°F (108 – 70 = 38). In these outdoor conditions, evaporative coolers would work very well. However, in Sarasota, Florida, when the outdoor temperature is 92°F and the coincidental wet-bulb temperature is 79°F, the wet-bulb depression is only 13°F (92 – 79 = 13); here an evaporative cooler would not work very well. The 1% summer design wet-bulb temperatures in the United States are shown in Figure 6. As a general rule, areas with wet-bulb temperatures of 70°F or lower are appropriate for evaporative cooling. See the Climate tab for more information.

The efficiency of evaporative coolers is not measured in SEER (seasonal energy efficiency ratio), which is the efficiency measurement used for standard air conditioning systems. There is no national or international testing organization for rating evaporative coolers, although some guidance for testing can be found in ANSI/ASHRAE Standard 133-2008. Instead, manufacturers refer to the cooling effectiveness of evaporative coolers, which is a measure of how close the temperature of the supply (leaving) air is to the wet-bulb temperature of the outdoor air entering the evaporative cooler. If the supply air temperature were the same as the wet-bulb temperature of the outdoor air, the cooling effectiveness would be 100%.

The formula used to calculate cooler effectiveness is:

Where:

e = the cooling effectiveness of the cooler

TDB = the outdoor dry-bulb temperature

TWB = the outdoor wet-bulb temperature

SAT = the supply air temperature leaving the evaporative cooler

Note: TDB - TWB = the wet-bulb depression

An evaporative cooler that is delivering conditioned air into the home at 74°F when the outdoor conditions are 108°F dry-bulb and 70°F wet-bulb would have the following cooling efficiency:

e = (108 - 74) / (108 - 70)

e = (34) / (38) = 0.89 OR 89%

In the example, the cooler’s efficiency is 89%, which would be considered an efficient evaporative cooler.

Newer evaporative coolers have thick media with efficiencies (cooling effectiveness) of 75% to 93%. For example, 12-inch-thick media can have an efficiency of 90% or better. If you know the dry-bulb and wet-bulb temperature and the media manufacturer’s effectiveness rating for the media, you can calculate what the supply air temperature is likely to be. For example, if the outside air’s dry-bulb and wet-bulb temperatures are 105°F and 60°F, the wet-bulb depression would be 45°F (105 - 60 = 45). If the single-inlet evaporative cooler is using a medium that is 90% effective, the discharge air temperature should be 105 - (45 x 0.9) = 64.5°F.

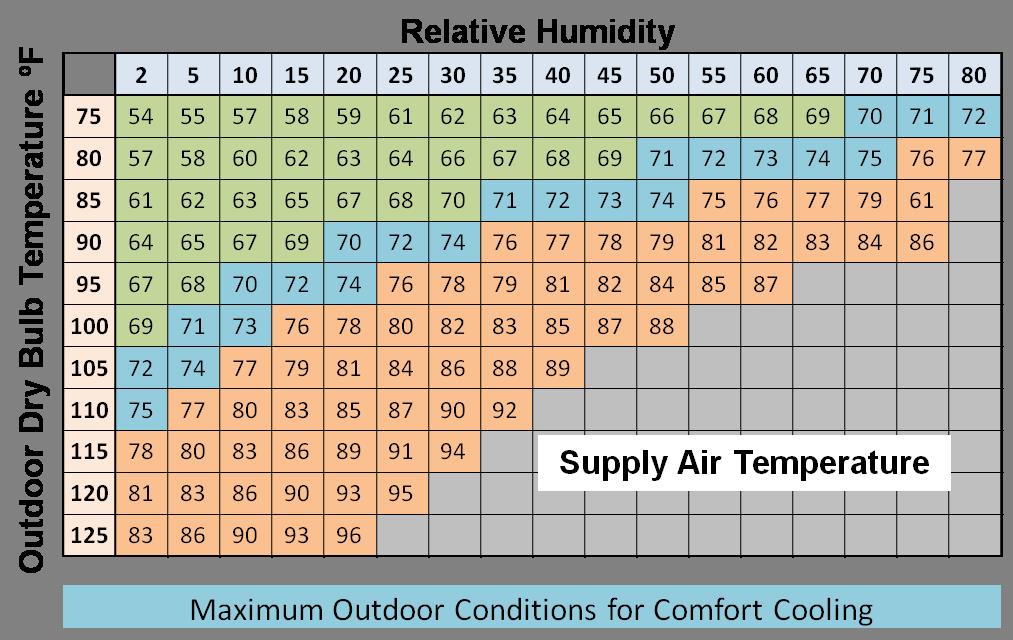

The chart in Figure 7 shows the supply air cooling temperatures that an aspen fiber evaporative cooler (about 70% effective) can provide at outdoor temperatures ranging from 75°F to 125°F at 2% to 80% relative humidity (relative humidity is directly related to wet-bulb temperature). The numbers in green represent supply air temperatures that can provide effective cooling for comfort conditions. The numbers in blue are borderline, and the numbers in red will generally not provide standard indoor comfort conditions, though they would improve indoor conditions significantly as compared to using no cooling at all.

Note how wet-bulb (WB) temperature impacts an evaporative cooler’s cooling ability as shown in Figure 7. On a day when the outdoor temperature is 100°F dry bulb (DB) at 10% relative humidity (RH) (63°F WB according to a psychrometric chart), the supply air entering the home will be 73°F DB, which is a 27°F DB temperature drop. However, if the outdoor temperature is at 95°F DB at 50% RH (79°F WB), the supply air temperature will be 84°F DB (only an 11°F DB temperature drop).

Sizing an evaporative cooler is not an exact science. Evaporative coolers are sized by airflow rate in cubic feet per minute (CFM). They are not sized by "tons of cooling” like standard air conditioners. Common evaporative cooler sizes range from 3,000 to 6,500 CFM.

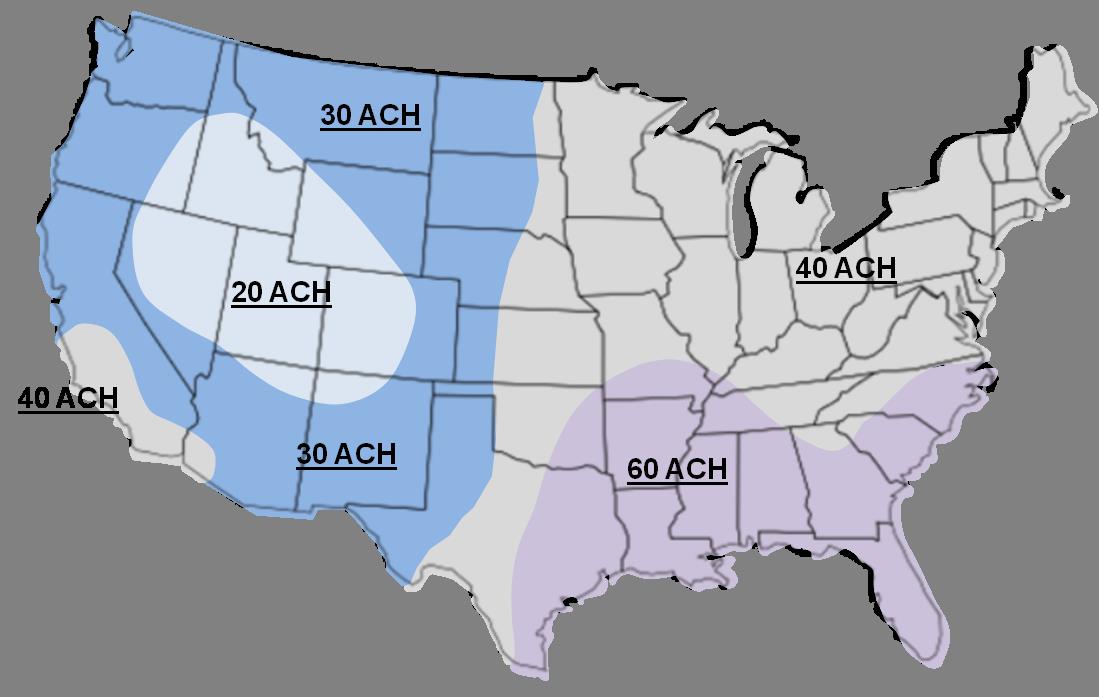

To determine what size unit is needed for a particular home, the concept of air changes per hour (ACH) is used. 1 ACH equals the amount of airflow required to completely replace the air volume of the house one time in one hour. For evaporative cooling, most manufacturers suggest installing a unit that can provide around 20 to 40 ACH through the conditioned space, depending on location and outdoor conditions. The map in Figure 8 shows the air changes per hour that an evaporative cooler would have to produce to provide comfort at that region’s 1% summer design wet-bulb temperature.

Based on the location of a particular house, the ACH required can be determined using this map. To determine your evaporative cooler system size:

For example, if we have a 2,000-ft 2 home with 8-ft ceilings located near Salt Lake City, Utah, according to the zone map, we should size the evaporative cooler so that it will provide 20 ACH. The volume of the conditioned space of the home is 16,000 ft 3 (2,000 x 8). So the formula would look like this: (16,000 x 20) ÷ 60 = 5,333 CFM.

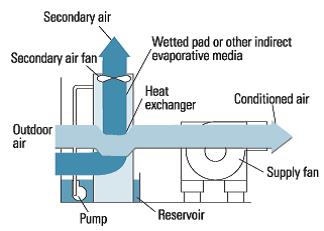

Indirect evaporative coolers use an air-to-air heat exchanger so they don’t add humidity to the cool air (Figure 9). This requires two separate air paths that exchange heat (or coolness) through a heat exchanger. The main supply fan supplies outside air that is cooled by passing through the heat exchanger as it is drawn into the home. A secondary fan draws exhaust air from the home and/or outside air through wet media, providing evaporatively cooled air, which then passes through the heat exchanger where it can cool the supply air stream without adding moisture to it. The moist secondary air stream is exhausted to the outside after passing through the heat exchanger.

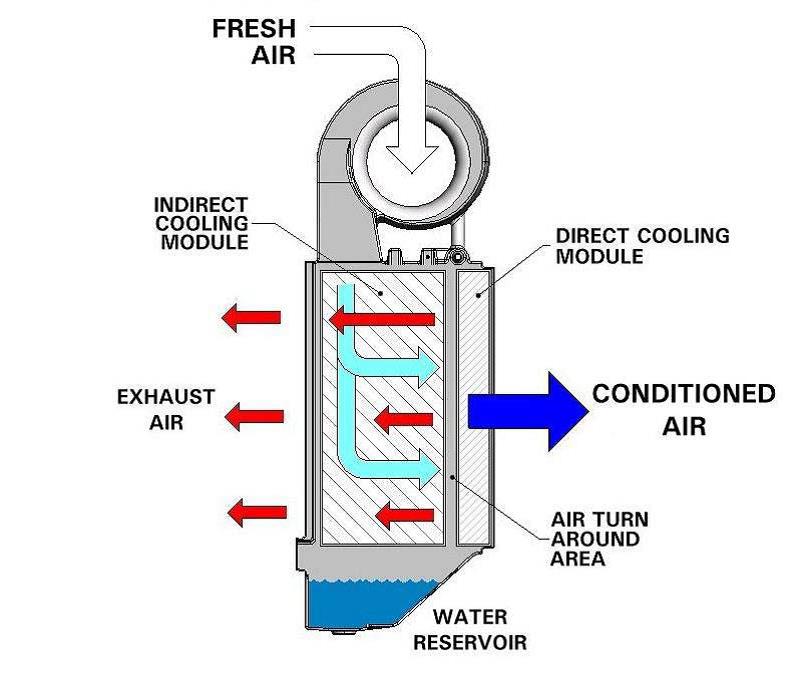

Indirect/direct coolers cool in two stages (Figure 10). In the first stage, the air passes through an indirect heat exchanger, which lowers the temperature without adding humidity. The air then enters the second, direct cooling stage where it flows through wet pads just like a direct evaporative cooler to be further cooled and humidified before flowing into the home. Because the air has been pre-cooled in the first stage, when it leaves the second stage it is cooler and has less moisture than the air leaving the single-stage unit. This technology achieves an evaporative cooling efficiency of 95% or greater (PG&E 2004).

Another innovative evaporative technology is the water-cooled evaporative condenser, which is a scaled-down residential version of the large, water-cooled chillers used in commercial buildings. Inside the housing, a mist of water is continually sprayed on the condenser coils to remove heat from the refrigerant and at the same time reduce the work of the compressor. Unlike traditional air conditioners, which use 10% more power for each 10°F increase in temperature above 95°F, an evaporative-cooled condenser draws the same power over a wide range of outdoor temperatures. These units use about half the energy of conventional “air-cooled” condensing units.

Evaporative coolers have been developed that use photovoltaic (PV) panels to create the electricity used to run the blower and the water pump. For hot desert areas, the combination of evaporative cooling and solar power is a perfect match: the afternoon, when solar energy is available, is also the hottest part of the day, when cooling is most needed. And, because evaporative coolers use a fraction of the energy of air conditioners, PV cells can provide enough electricity to run the system effectively (SWEEP 2007).

How to install an Evaporative Cooler

If connected to a ducted system, follow duct installation best practices . This includes duct design, duct sealing, and air tightness testing. See ENERGY STAR HVAC System 6 Duct Quality Installation guidance in the ENERGY STAR checklist.

Evaporative coolers work best and supply the most comfort in dry climates where the 1% summer design wet-bulb temperatures are below 70°F (region “A” in Figure 1). Evaporative coolers can provide cooling in climates where coincidental wet-bulb temperatures are as high as 74°F but high humidity will reduce performance (Region “B” in Figure 1). In these areas, indirect evaporative cooling may be best.

from IECC 2009, 12, 15, and 18. " width="539" height="347" />

from IECC 2009, 12, 15, and 18. " width="539" height="347" />

Compliance

The Compliance tab contains both program and code information. Code language is excerpted and summarized below. For exact code language, refer to the applicable code, which may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

The EPA WaterSense Home Specification does not require that evaporative cooling systems are installed. However, if installed, these systems may contribute to the 30% efficiency requirement.

As a best practice, it is recommended that individual evaporative cooling systems shall use a maximum of 3.5 gallons (13.3 liters) of water per ton-hour of cooling when adjusted to maximum water use. Blowdown shall be based on time of operation, not to exceed three times in a 24-hour period of operating (every eight hours). Blowdown shall be mediated by conductivity or basin water temperature-based controllers. Once-through or single-pass cooling systems, systems with continuous blowdown/bleed off, and systems with timer-only mediated blowdown management shall not be used to meet these criteria.

Exhibit 1 Mandatory Requirements.

Exhibit 1, Item 1) Certified under the ENERGY STAR Qualified Homes Program or the ENERGY STAR Multifamily New Construction Program.

Exhibit 2 DOE Zero Energy Ready Home Target Home.

The U.S. Department of Energy’s Zero Energy Ready Home program allows builders to choose a prescriptive or performance path. The DOE Zero Energy Ready Home prescriptive path requires builders to meet or exceed the minimum HVAC efficiencies listed in Exhibit 2 of the National Program Requirements (Rev 07), as shown below. The DOE Zero Energy Ready Home performance path allows builders to select a custom combination of measures for each home that is equivalent in performance to the minimum HERS index of a modeled target home that meets the requirements of Exhibit 2 as well as the mandatory requirements of Zero Energy Ready Home Exhibit 1.

Footnote 21) DOE recommends, but does not require, that cooling systems in hot/humid climates utilize controls for immediate blower shutoff after condenser shutoff, to prevent re-evaporation of moisture off the wet coil.

Footnote 22) Air source heat pumps with electric resistance backup cannot be used in homes qualified in Climate Zones 7 & 8 using the Prescriptive Path.

2009 International Energy Conservation Code (IECC)

403.1 Each heating and cooling system should have its own thermostat. If the primary heating system is a forced-air furnace at least one thermostat must be programmable and capable of controlling the heating and cooling system on a schedule to maintain different temperatures at different times of the day.

403.2 Ducts - Insulate supply ducts in attics to at least R-8 and all other ducts to at least R-6. Duct tightness shall be verified as described in 403.2.2 Sealing.

403.6 Heating and cooling equipment sizing shall be in accordance with Section M1401.3 of the 2009 International Residential Code.

2012 IECC

403.1 Each heating and cooling system should have its own thermostat. If the primary heating system is a forced-air furnace, at least one thermostat must be programmable and capable of controlling the heating and cooling system on a schedule to maintain different temperatures at different times of the day.

403.2 Ducts - Insulate supply ducts in attics to at least R-8 and all other ducts to at least R-6. Duct tightness shall be verified as described in 403.2.2 Sealing.

The air handler shall have a manufacturer’s designation showing air leakage is no more than 2% of the design air flow rate when tested in accordance with ASHRAE 193.

403.6 Heating and cooling equipment shall be sized in accordance with ACCA Manual S based on building loads calculated in accordance with ACCA Manual J or other approved heating and cooling calculation methods.

R403.1 Each heating and cooling system should have its own thermostat. The thermostat controlling the primary heating and cooling system of the dwelling unit shall be capable of controlling the heating and cooling system on a daily schedule to maintain different temperature set points at different times of the day and week.

403.3.1 Insulation (Prescriptive). Supply and return ducts in attics insulated to at least R-8 if 3 inches in diameter or more or R-6 if less than 3 inches. Duct tightness verified as described in R403.3.2 (R403.3.4 in 2021 IECC) Sealing.

403.7 Heating and cooling equipment shall be sized in accordance with ACCA Manual S based on building loads calculated in accordance with ACCA Manual J or other approved heating and cooling calculation methods.

Section R101.4.3 (in 2009 and 2012). Additions, alterations, renovations, or repairs shall conform to the provisions of this code, without requiring the unaltered portions of the existing building to comply with this code. (See code for additional requirements and exceptions.)

Chapter 5 (in 2015, 2018, 2021). The provisions of this chapter shall control the alteration, repair, addition, and change of occupancy of existing buildings and structures.

Existing HomesAssess the need for replacing, upgrading, or adding cooling equipment. DOE’s Standard Work Specifications describes practices to complete whole-house energy upgrades safely without injury or hazardous exposure in the section on Global Worker Safety.

Standard Work Specification guidance on evaporative cooler maintenance and repairs lists potential areas to assess and repair.

The typical lifespan of HVAC equipment is 15 to 20 years. Evaporative coolers have few working parts, many of which can be easily and cheaply replaced. However, the cabinet and metal components are very susceptible to rusting and calcification; therefore, the failure of any component, most often the fan, should prompt assessment of the cabinet and other components. The best, most cost-effective choice may be to replace the entire unit. See the following BASC guides:

If a decision is made to replace the equipment, it can be replaced with the same kind of equipment, or with a more efficient form of evaporative cooler such as an indirect evaporative cooler or a two-stage indirect/direct evaporative cooler (see the Description tab), or with a different type of cooling system such as a standard air conditioning system or heat pump. Evaporative coolers are most effective in dry climates where the 1% design wet bulb temperature is below 70°F. In humid climates choose standard mechanical air-conditioning and heat pumps, which also offer the advantage of de-humidification.

See the following guides for more information on other types of HVAC systems that provide cooling:

Full system maintenance is often overlooked by homeowners who don’t understand the strong relationship between general maintenance and performance. Debris, rust, and calcification can all diminish efficiency and performance. Evaporative coolers should be inspected and have maintenance conducted at least twice a year, when the unit is first started up in the spring and when it is shut down in the winter, as noted under the Description tab. Check the tension on the fan belt and lubricate the blower assembly bearing motor. Replace torn, worn or mildewed cooler pads. Check water nozzles to make sure they are aimed to saturate the pads and clean them with vinegar to remove calcification. Make sure the tray is water-tight and repair any holes or cracks. Ensure the float operates properly.

Winterize the cooler by draining and drying completely and removing mineral deposits, especially at jointed or moving parts associated with the fan, the water spray nozzles, and the tray. Cover the entire unit with a plastic or canvas cover and close dampers if the unit is centrally ducted. If the unit is mounted in a window, completely remove it and store it elsewhere, so the windows can be shut during the winter season.

More Info.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.